a modern decision-support system (DSS) for efficient management of sawmills and woodworking mills

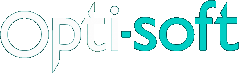

The Opti-Sawmill system was developed specifically for sawmills and woodworking mills as a tool for planning, optimizing and managing production and sales.

The system allows to solve the following economic tasks:

- increase the yield of lumber,

- increase profitability ("marginality"),

- reduce the cost of raw materials,

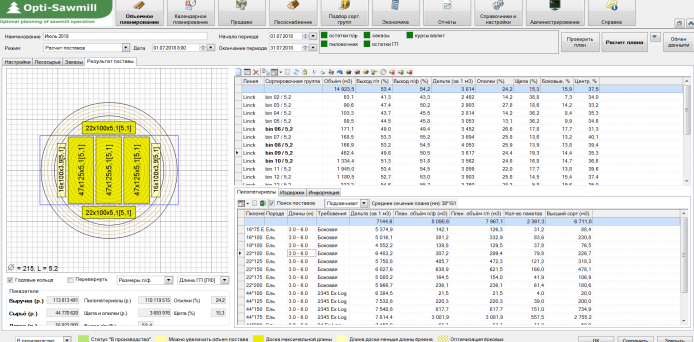

- shorten the orders execution time,

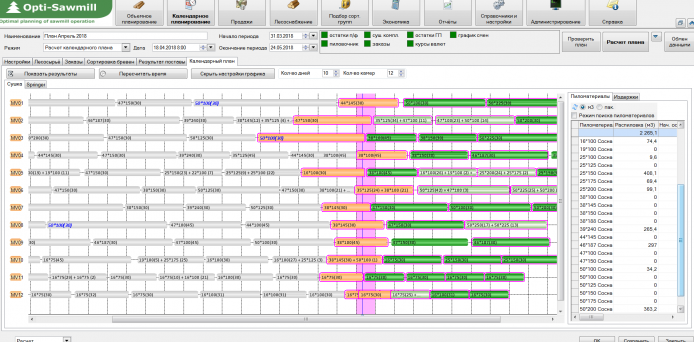

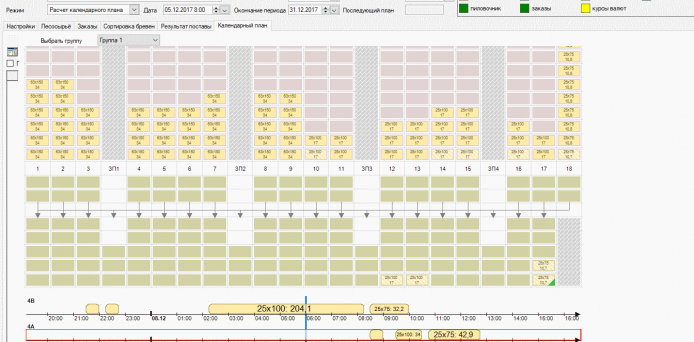

- reduce the time spent by personnel on planning and control procedures,

- generate new sawing patterns and compare their profitability,

- evaluate the profitability of incoming orders.

Increased volume yield and profitability of sawn timber production

Increased volume yield and profitability of sawn timber production  Reduction of time spent by personnel on planning and control procedures due to automation of these processes

Reduction of time spent by personnel on planning and control procedures due to automation of these processes  Increased efficiency of obtaining information on key performance indicators of the mill as a whole, and individual orders

Increased efficiency of obtaining information on key performance indicators of the mill as a whole, and individual orders  Reduction of in-process inventory at all levels by end-to-end planning and optimization throughout the entire production chain

Reduction of in-process inventory at all levels by end-to-end planning and optimization throughout the entire production chain  Reduction of production orders execution time due to reduced equipment downtimes and tighter schedule

Reduction of production orders execution time due to reduced equipment downtimes and tighter schedule